Batch fermentation and continuous culture

Microorganisms can be used and modified to perform industrial processes.

Microorganisms are small and grow quickly. There is a huge diversity of them including, bacteria of many sorts, archaebacteria and fungi. They are useful in industry because their metabolism has the capacity to produce a range of natural metabolites. This can also be optimised by pathway engineering illustrated by penicillin and citric acid production.

Microorganisms are small and grow quickly. There is a huge diversity of them including, bacteria of many sorts, archaebacteria and fungi. They are useful in industry because their metabolism has the capacity to produce a range of natural metabolites. This can also be optimised by pathway engineering illustrated by penicillin and citric acid production.

Lesson Description

Guiding Questions

Describe what you see in the image. What does it make you think? What unanswered questions do you have?

click image to enlarge

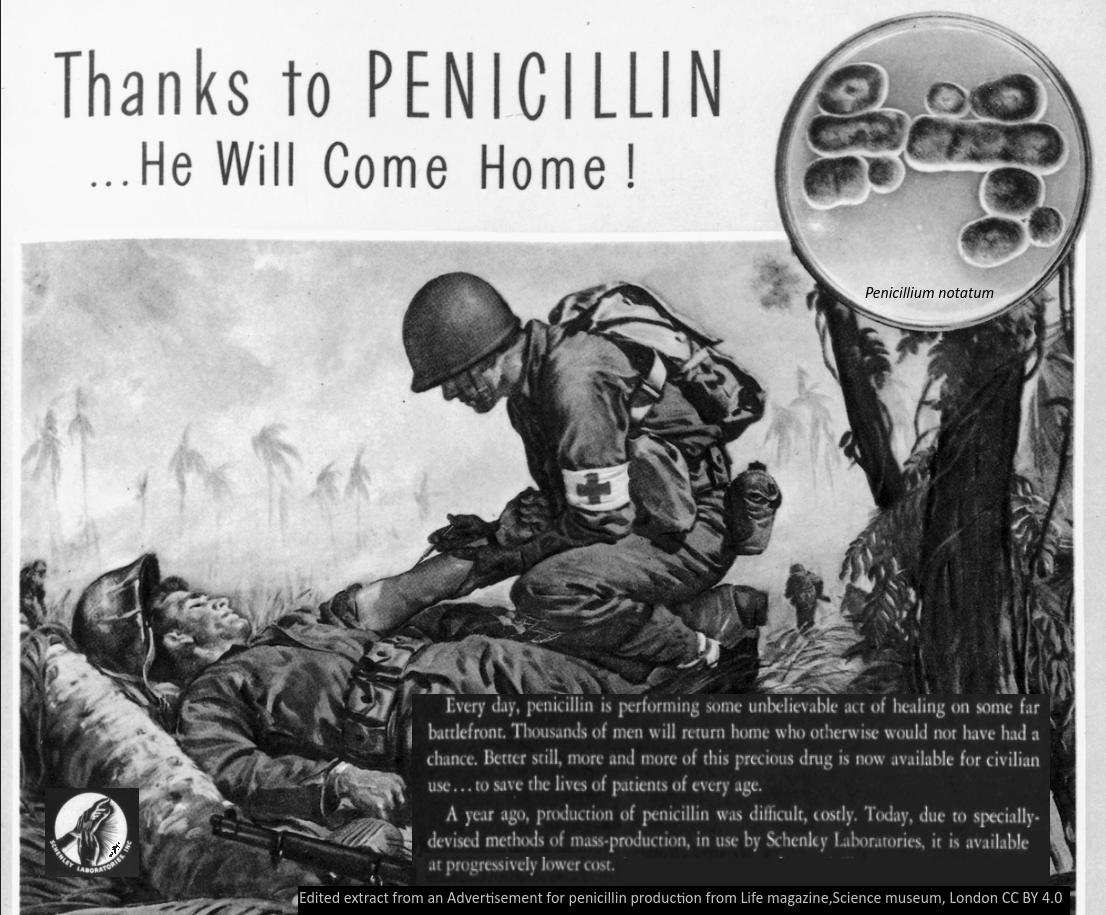

Injured soldier on battlefield is getting an injection.

The round insert is a microscope image of some Penicillium fungus.

The caption suggests that the treatment is penicillin and this is saving his life.

What does the penicillin do? This is not explained.

The production of penicillin will be available to everyone.

Activity 1 - Batch fermentation in the mass production of penicillin

After the discovery of penicillin had been proven to

The first industrial manufacture of penicillin in 1945 was considered a miracle. Before the discovery of antibiotics a bacterial infection from a simple cut or a fractured bone could kill a healthy person.

Watch this 1945 news reel outlining an early example of batch fermentation and consider the questions below.

Discuss

What is a fermentation batch?

What types of health problems can the "life saving" treat, according to this 1945 film?

Why are the rabbits used during the production?

This great video, introduces fermentation to make a wide range of different products.

Watch the video and answer the questions in the worksheet below.

Answer the questions on the ![]() Batch fermentation video questions worksheet below while watching the video.

Batch fermentation video questions worksheet below while watching the video.

This will create a good set of summary notes.

Activity 2 - Production of biogas in a small-scale fermenter

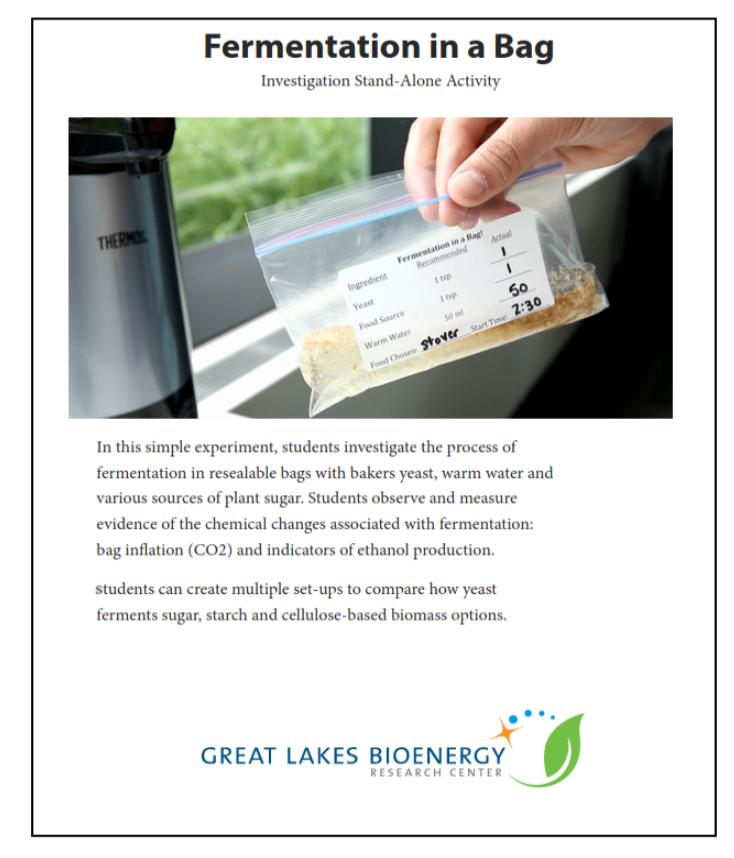

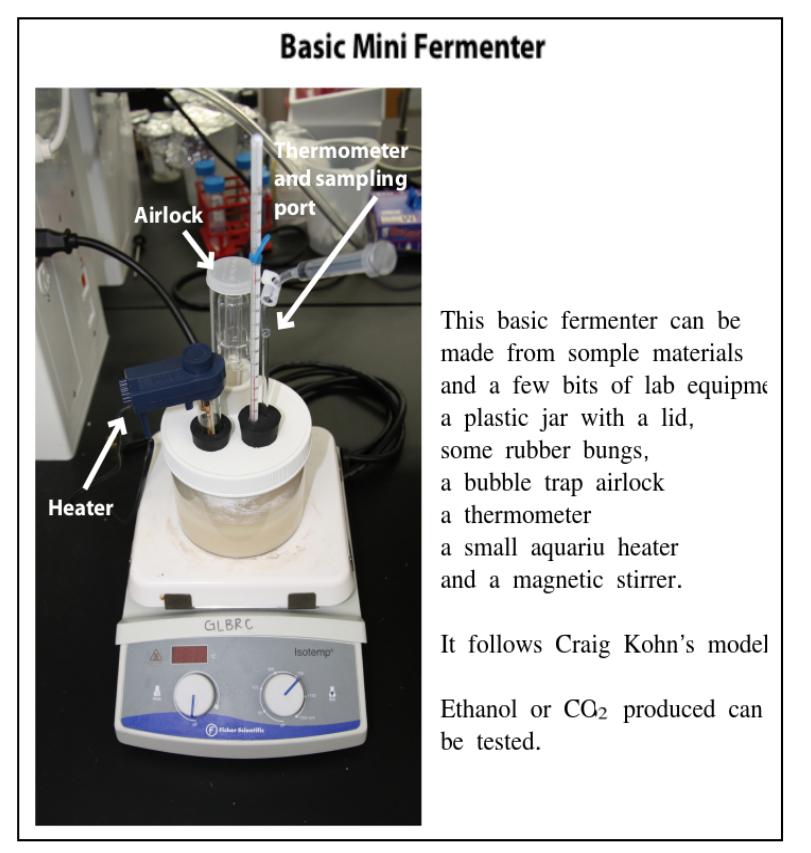

Biogas is produced by bacteria and archaeans from organic matter in fermenters. It is quite easy to replicate this process on a small scale in the lab. There are three suggestions for this experiment. The first is very simple, the second is more complex but flexible, and the last involves a DIY system.

|  |  |

Great Lakes bioenergy research center website of resources for mini fermenter. |

- Probes are used to monitor conditions within fermenters.

- Conditions are maintained at optimal levels for the growth of the microorganisms being cultured.

Activity 3 - Continuous culture to produce citric acid by Aspergillus niger

- Batch fermentation is used to produce penicillin, in deep-tank batch fermentation.

- Fermentation by continuous culture is used to produce citric acid by Aspergillus niger (used as a flavouring or preservative.)

Question

How is the process of continuous culture different from the batch culture used to make Penicillin and GFP?

..................................................................................................................................

..................................................................................................................................

..................................................................................................................................

Teachers' notes

Activity 1

The first two videos set the scene and to introduce the basics of batch cultures and their benefits. The videos show how the use of simple glassware, aluminium foil and cotton wool were important in 1945, and the third video shows how modern methods are more sophisticated and can produce a product much faster because the conditions are optimised for the organism.

There are model answers for this activity here: Batch fermentation video questions - model answers

Teachers can control student access to the model answers using the Student access controls in the teacher's user account.

This is an alternative video - slightly longer but tells the story of discovery and production very well.

For those who like to read more, this website gives a nice written history of penicillin production:

https://70691396.weebly.com/mass-production.html

Activity 2

Practical work in the growth of bacteria, the effectiveness of bacteriocides (but not antibiotics) is mentioned in the IB Bio guide.

The three examples suggested cover a range of options depending on resources in school.

There are quite a few alternative designs of bioreactor and this list shows three.

- Small affordable bioreactors - could be used in school for experiments. https://makezine.com/2016/07/18/arduino-powered-bioreactors-make-home-experimentation-affordable/

- A good looking simple kit. https://www.biomaker.org/projects/the-big-algal-open-experiment

- A plastic bottle bioreactor. http://compost.css.cornell.edu/soda.html

Activity 3

The guide mentions the production of citric acid by continuous culture - while there are many similarities in this process, a comparison between batch culture and continuous culture seems an effecient way to illustrate the particularities of continuous culture.

These differences include, continuous addition of nutrients in the sterile media and the outflow of microbial cells, their product and media.

Checklist for the teacher of the details to cover

- Microorganisms are metabolically diverse organisms used in industry because they are small and have a fast growth rate.

- Useful metabolite production in industry can be optimised by pathway engineering of genetic and regulatory processes in microorganisms..

- Large-scale metabolite production by microorganisms takes place in fermenters.

- Batch fermentation is used to produce penicillin, in deep-tank batch fermentation.

- Fermentation by continuous culture is used to produce citric acid by Aspergillus niger (used as a flavouring or preservative.)

- Microorganisms in fermenters become limited by their own waste products.

- Probes are used to monitor conditions within fermenters.

- Conditions are maintained at optimal levels for the growth of the microorganisms being cultured.

- Biogas is produced by bacteria and archaeans from organic matter in fermenters.

Skills

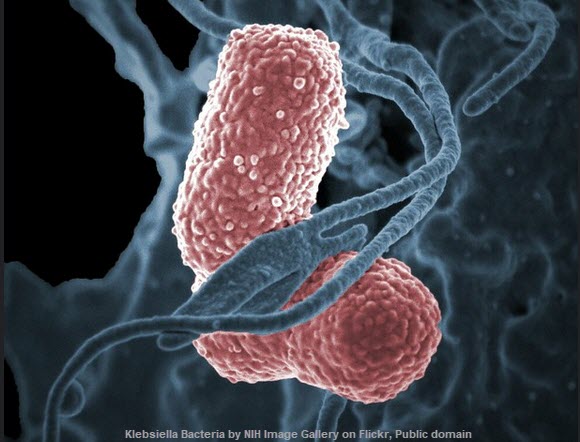

- Students should understand how to carry out Gram staining of Gram-positive and Gram-negative bacteria.

- Students should carry out experiments with known safe bacteria, showing zone of inhibition of bacterial growth by bactericides.

- Students should have experience of production of biogas in a small-scale fermenter.

IB Docs (2) Team

IB Docs (2) Team