Immobilised Enzymes

Immobilised enzymes are widely used in industry

- Just before 1900, it was discovered that enzymes could be used to catalyse production of alcohol in the absence of yeast cell

- Since then, hundreds of enzymes have been developed outside of living cells for commercial purposes

- Uses of enzymes in industrial processes can be expensive, so we need ways to reuse them in order to be cost-effective

- An immobilised enzyme is an enzyme that is attached to an insoluble material to prevent mixing with the product and through this method, the enzyme can be reused in subsequent reactions

- Immobilised enzymes are used in the following commercial processes

- Agriculture

- Biosensors (diagnosis, analysis eg. for impurities)

- Manufacturing processes

- Energy generation

- Environmental management

- Food/drinks industry

- Medicines

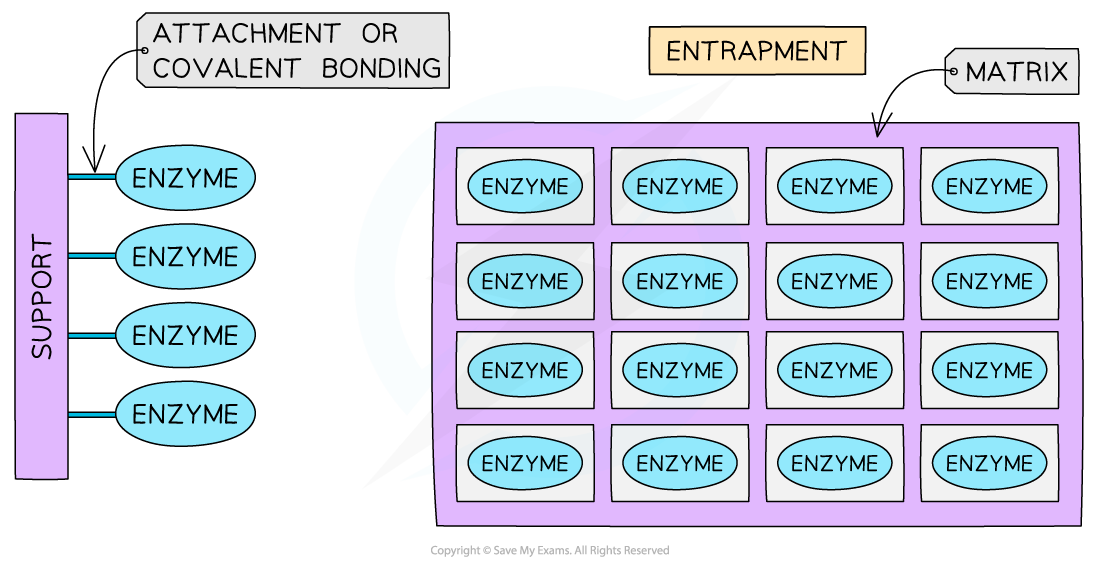

- Methods by which enzymes can be immobilised include:

- Attachment to an inert substance eg. glass

- Entrapment within a matrix e.g. alginate gel

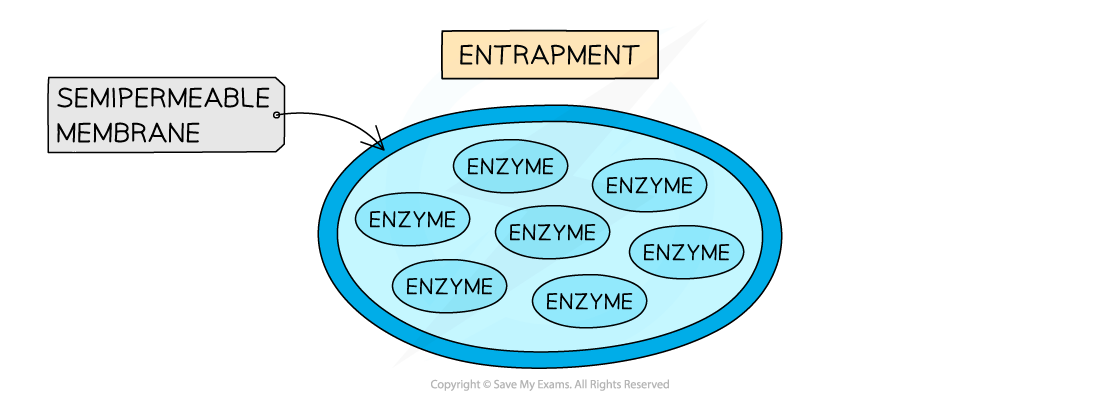

- Entrapment within a partially permeable membrane

Different ways in which enzymes can be immobilised

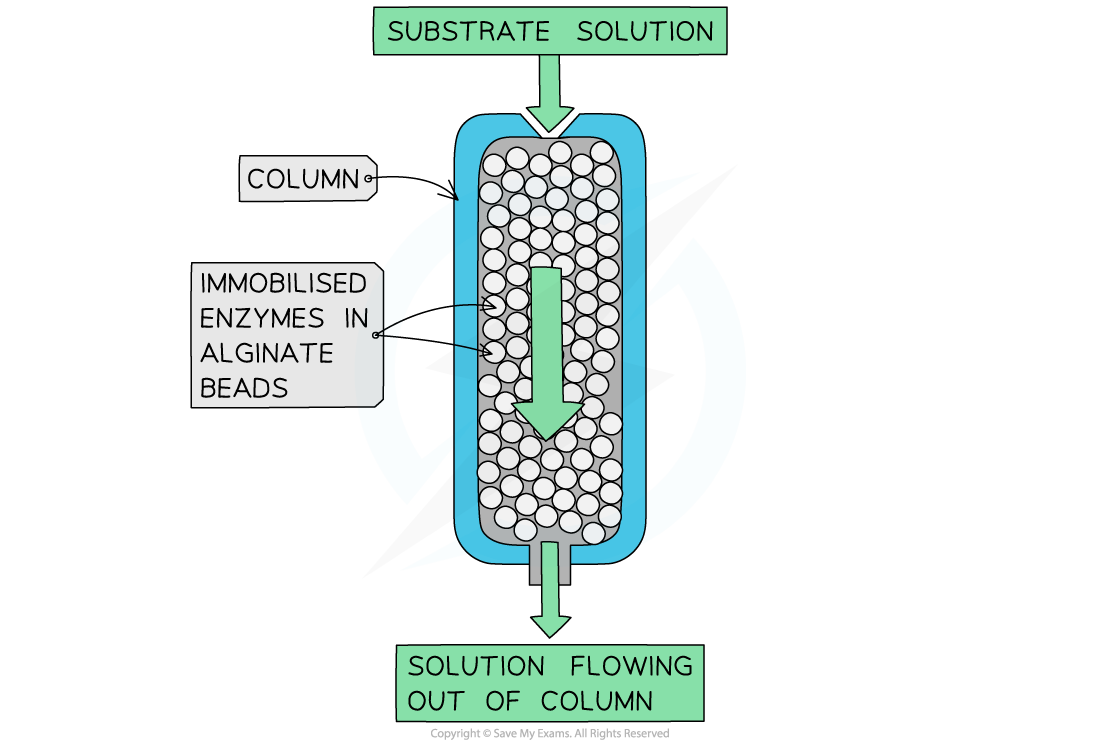

- The mechanism of immobilised enzyme use works as follows:

- The immobilised enzymes are contained within a column

- The substrate is filtered through this column in solution

- As the substrate runs through the column, enzyme-substrate complexes are formed and products are produced

- These products then flow out of the column, leaving the enzymes behind to catalyse the reaction again

The immobilised enzymes are contained within a column

Advantages of immobilised enzymes

- There is no enzyme in the product (the product is uncontaminated) and therefore there is no need to further process or filter the end product

- The immobilised enzyme can be reused multiple times which is both efficient and cost-effective (many enzymes are expensive)

- Reusing the enzyme also avoids the need to separate the enzyme from the product in downstream processing

- Immobilised enzymes have a greater tolerance of temperature and pH changes (immobilisation often makes enzymes more stable)

- Substrates can be exposed to higher enzyme concentrations than when using enzymes in solution, increasing the rate of throughput

- Conditions can be controlled carefully, allowing immobilised enzymes to function close to their optimum conditions and be more stable

Disadvantages of immobilised enzymes

- Specialist expensive equipment is required

- Immobilised enzymes are more costly to buy, so are unlikely to be financially worthwhile for smaller industries

- The rate of reaction is sometimes lower when using immobilised enzymes as the enzymes cannot mix freely with the substrate

Examples of immobilised enzymes in industry

- There are many industrial and medical applications of immobilised enzymes, including production of the following:

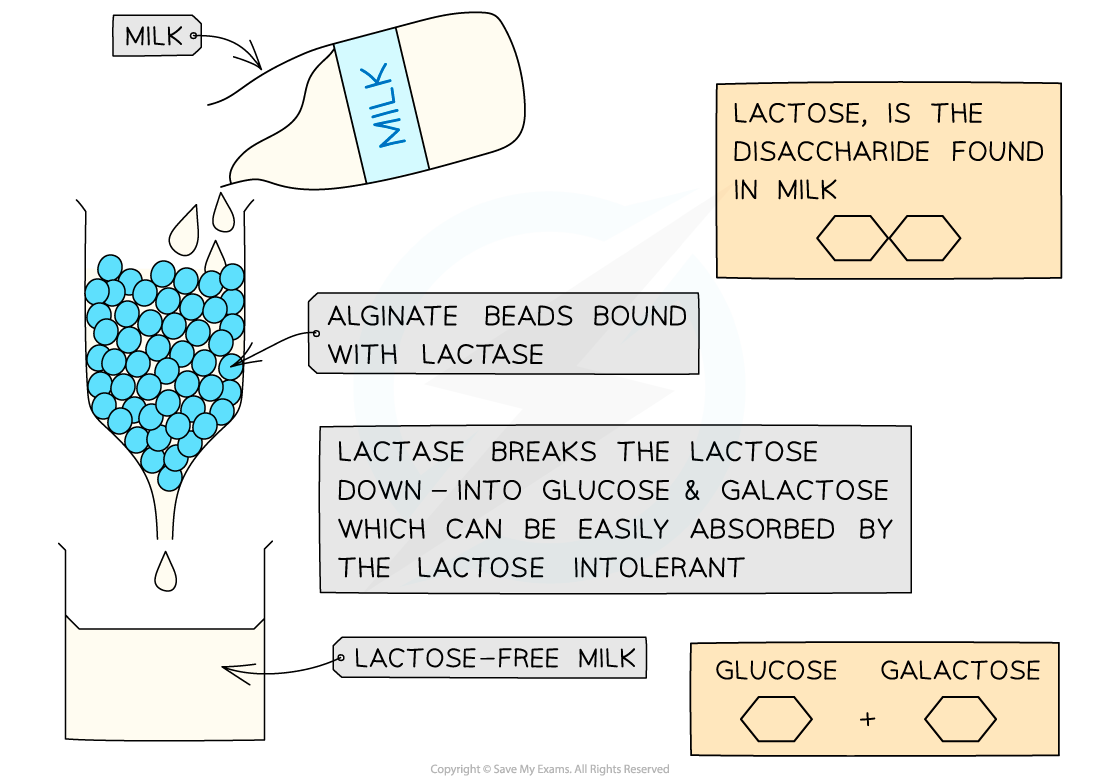

- Lactose-free dairy products such as milk

- Enzyme: Lactase

- Converts lactose to glucose and galactose

- Semi-synthetic penicillin which overcomes issues of penicillin resistance

- Enzyme: Penicillin acylase

- Converts the original form of penicillin into one which is effective against penicillin-resistant organisms

- Glucose products used to sweeten and thicken foods

- Enzyme: Glucoamylase

- Converts starch and other dextrins into glucose

- Fructose for sweetening of foods where a lower quantity of sugar is necessary

- Enzyme: Glucose isomerase

- Converts glucose into the sweeter sugar, fructose

- Purified samples of L-amino acids used in food production

- Enzyme: Aminoacylase

- Separates out L-amino acids from D-amino acids

- Acrylamide required in disposable nappy/diaper production

- Enzyme: Nitrilase

- Converts acrylonitrile into acrylamide

- Lactose-free dairy products such as milk

Exam Tip

You will not necessarily be asked about these specific examples of industrial uses of immobilised enzymes (except for lactose modification), but it is useful to know of some uses in order to be able to apply your knowledge accurately in the exam.When discussing the advantages and disadvantages of immobilised enzymes, try to be specific about the cost implications as there are various considerations when it comes to the economical value of immobilising the enzymes.

Lactose-free Milk Production

A closer look at lactose-free milk production

- Milk is a valuable source of nutrients containing protein, fat and the carbohydrate lactose

- 5-10% of the UK population are lactose intolerant

- They can't digest lactose and suffer from bloating, digestive problems, discomfort and pain

- Lactose is a disaccharide that is hydrolysed into glucose and galactose

- The yeast Kluyveromyces lactis grows naturally in milk and can be cultured as a source of the enzyme lactase

- Glucose and galactose are sweeter than lactose, so less sugar needs to be added to foods with modified lactose to achieve the same sweetness

- Ice cream and yoghurt production also benefit from having more glucose and galactose than lactose in the milk they are made from

Using the immobilised enzyme lactase to modify milk